_

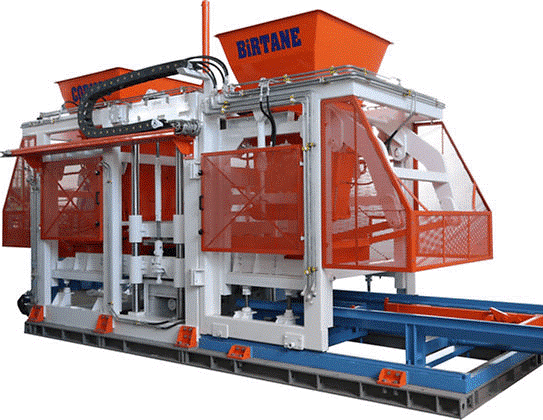

COB 1236 – High Performance Block & Interlock Machine

Maximum Productivity in Every Press

-

Interlock Production: Delivers 1 sqm per press for fast and efficient paving stone output.

-

Block Production: Capable of producing 12–15 hollow or solid blocks (20x40x20 cm) in a single press.

-

Cycle Time: Only 18–20 seconds per press, ensuring high-volume daily production.

Advanced Hydraulic Technology

-

Equipped with a proportional valve and pump system for smooth, consistent operation.

-

Max Hydraulic Pressure: 350 bar.

-

Operational Pressure: Works reliably at up to 250 bar.

Powerful Vibration System

-

Down Vibration: 96 KN centrifugal force for maximum compaction.

-

Upper Vibration: 32 KN for perfect finishing.

-

Smart Control: Vibration motors are AC-driven and fully programmable.

-

Adjustable Settings: Vibration percentage can be fine-tuned according to product requirements.

Built for Performance & Flexibility

The COB 1236 combines strength, speed, and intelligent control, making it the ideal solution for producing both interlock and concrete blocks with superior quality and efficiency.

_

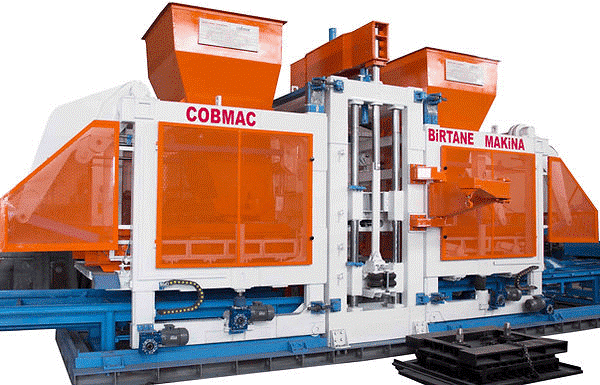

COB 1230 – Reliable Block & Interlock Machine

Productivity

-

Produces with square table size

-

12–12.5 hollow/solid blocks (20x40x20 cm) per press

-

Cycle time: 22–24 seconds per press

Hydraulic System

-

Strong hydraulic structure with advanced controls

-

Max pressure: 250 bar | Working pressure: 160 bar

Vibration System

-

Down vibration: 64 KN

-

Upper vibration: 16 KN

-

Controlled by AC driver with adjustable vibration percentage (programmable per product)

Key Advantage

The COB 1230 offers a perfect balance of efficiency, precision, and durability, making it a smart choice for block and interlock production.

_

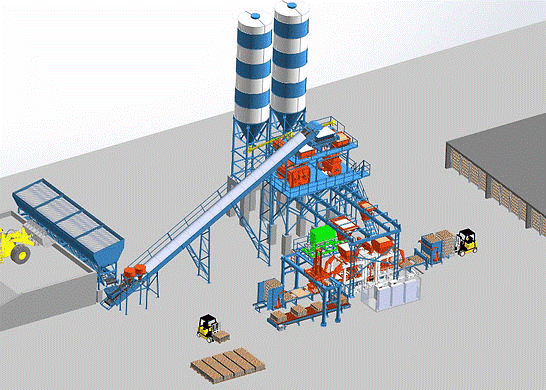

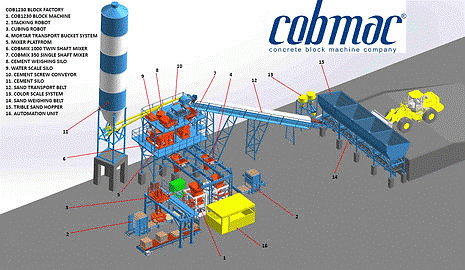

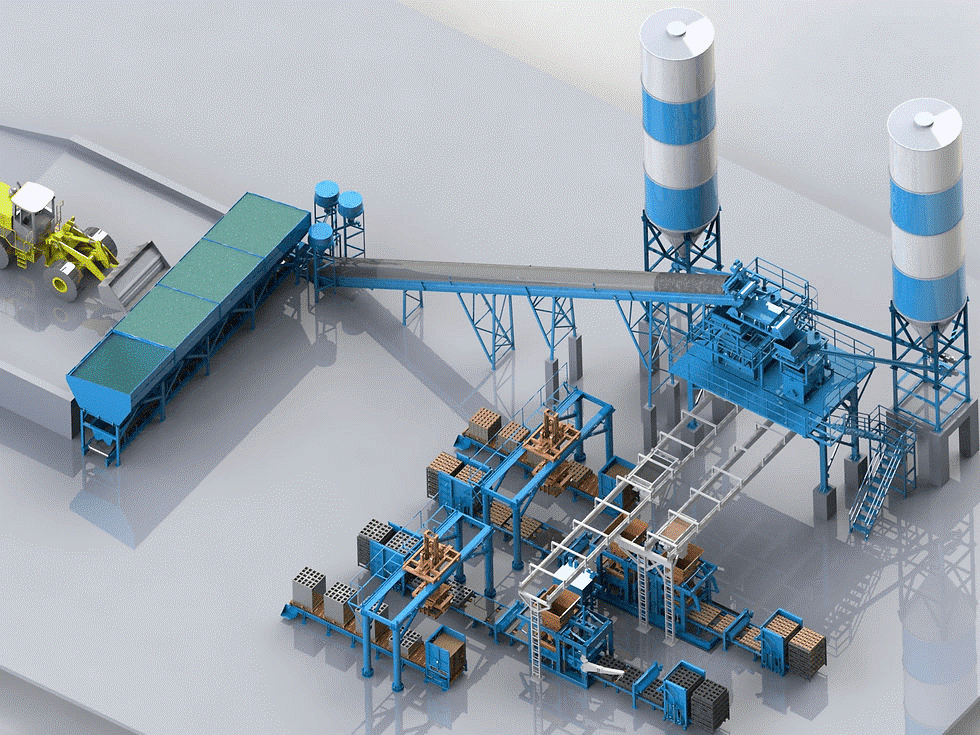

COBMAC Concrete Batching & Mixing Plant

The Concrete Batching & Mixing Plant is the core of every block and interlock production line. Designed by COBMAC for maximum efficiency, it delivers a precise and consistent concrete mix that guarantees high-quality products.

Equipped with an automated dosing system, the plant accurately measures cement, sand, gravel, water, and additives, ensuring every batch meets exact production requirements. A high-capacity mixer blends the raw materials into a uniform mix, which is then transported directly to the block machine hopper via conveyor or skip system.

With its fully automated control system, operators can easily monitor and adjust recipes, production capacity, and material flow, achieving consistent strength, durability, and performance in every block and interlock produced.

Key Benefits:

-

Precise and automated material dosing

-

Consistent, high-quality concrete mix

-

Seamless integration with COBMAC block & interlock machines

-

Reliable performance for continuous, large-scale production

The COBMAC Mixing Plant is engineered to be the reliable heart of your factory, ensuring smooth operation and top-quality end products.

Get in touch with us …